When it comes to the starter motor, the Lucas TVS starter motor stands first on the list. Apart from two-wheelers and cars, the starter motor device is used for stop-start function in most industrial plants. However, there are so many interesting things to know about the starter motor. It is interesting to know about the starter motor which you use every day, but do not know how it functions and when it started.

What is a Starter Motor?

The starter motor is a kind of device that is capable of turning the internal combustion engine to run repeatedly until the ignition starts. Once the engine starts running under its own power, the starter motor separates itself from the engine.

When was Starter Motor Invented?

You may have seen how a lawnmower machine starts, right? The same method was applied over a century back (before 1912) to ignite a vehicle. Earlier, a starter motor was human-powered and the driver would use a crank to start vehicles. To start the engine, the crank is inserted into the space given into the front of the engine. The driver needed to spin the handle and remove it when the engine got started.

The same process continued till 1912 when Cadillac invented the electric starter motor. Gradually, by 1920 most of the cars and other machines adopted electric starters. Earlier till 1960, the Bendix drive starter was very popular in the market. Then after most of the machine and vehicle companies began manufacturing their own starter motor.

Lucas TVS Starter Motor is one of the best companies, providing a range of starter motors for Two-wheelers, Direct drive, and starter-based stop-start solutions. Lucas TVS not only provides starter motors but also offers a complete system solution in Auto electricals, Ignition products, Engine cooling modules, specialized motors, etc.

How Lucas TVS Starter Motor Works

The working principle of a Lucas TVS starter motor is based on converting electrical energy from the battery into mechanical energy to rotate the engine. When you turn the ignition key, a small amount of current flows through the motor’s solenoid. This activates the motor, which then engages the flywheel of the engine. The flywheel spins, which in turn starts the engine.

Let’s break down the key components involved in the functioning of a Lucas TVS starter motor:

Solenoid

The solenoid acts like a switch that connects the battery to the starter motor. When the ignition key is turned, the solenoid allows a high current to flow from the battery to the motor. It also engages the starter pinion with the engine’s flywheel, enabling the engine to crank.

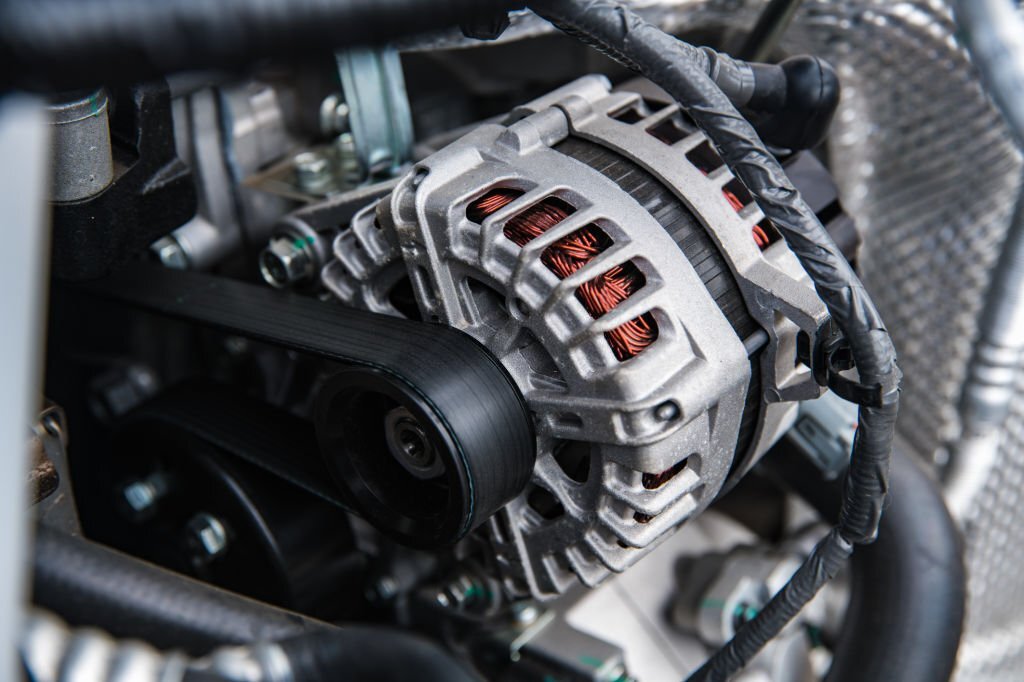

Armature

The armature is the rotating part of the starter motor. It consists of windings of copper wire, and when electrical current flows through these windings, it creates a magnetic field. This magnetic force causes the armature to rotate, which helps to turn the engine.

Commutator

The commutator plays a key role in the conversion of electrical energy to mechanical energy. It reverses the direction of current flowing through the armature windings, ensuring the armature keeps rotating in the same direction.

Brushes

The brushes in the Lucas TVS starter motor play a crucial role in transmitting current from the stationary component of the motor (stator) to the rotating element (armature). They are typically made of carbon and ensure smooth contact between the moving components.

What Features Do Lucas TVS Starter Motor Provide?

Lucas starter motor provides a range of features based on the type of vehicle. For example, for two-wheeler engines, the company provides starter motors, which are light-weight; provide integral and separate drive assembly options; feature high corrosion resistance, and work with both dry clutch & wet clutch applications.

For Direct Drive Vehicle: Direct drive vehicles include passenger cars as well as commercial vehicles and Lucas TVS starter motor suits every type of car and vehicle out in the market. The latest starter motor is made of a robust design for longer life while it is not affected by water and oil ingress.

Apart from that, the starter motor works with a gear reduction starter and also provides a stop-start solution. The motors have been designed, keeping all safety and optional features in mind.

In short, Lucas TVS offers a quality starter motor that gives a satisfactory result and comes with ample features.

Types of Lucas TVS Starter Motors

Lucas TVS offers two primary types of starter motors: direct-drive and gear-reduction starter motors. Each type has its own unique features and is suited for different applications.

Direct-Drive Starter Motors

A direct-drive starter motor is a simple and traditional design where the motor directly engages the engine’s flywheel. This type of starter motor generates a high torque at low speeds, making it ideal for larger engines. It’s known for being robust and is often used in commercial vehicles and heavy-duty applications.

Key Features of Direct-Drive Starter Motors:

- High torque output

- Simpler construction

- Suitable for large displacement engines

- Generally heavier in size

Gear-Reduction Starter Motors

A gear-reduction starter motor, on the other hand, uses a set of gears to increase the torque while reducing the size of the motor. This design allows for higher efficiency and a more compact motor. Gear-reduction motors are commonly used in passenger vehicles, where space and weight are crucial factors.

Key Features of Gear-Reduction Starter Motors:

- Lightweight and compact design

- Higher energy efficiency

- Suitable for smaller engines

- Lower current draw from the battery

Comparison of Direct-Drive vs Gear-Reduction Starter Motors

When comparing direct-drive and gear-reduction starter motors, each has its pros and cons depending on the application. Direct-drive motors are robust and can handle heavy engines, but they are larger and consume more power. Gear-reduction motors, on the other hand, are more energy-efficient, lighter, and better suited for smaller vehicles where space and weight are key concerns.

Advantages of Lucas TVS Starter Motors

Lucas TVS starter motors stand out in the market for several reasons, particularly when it comes to durability, reliability, and cost efficiency.

Durability and Reliability in Harsh Conditions

One of the major advantages of Lucas TVS starter motors is their ability to withstand harsh conditions. Whether you’re dealing with extreme temperatures, dust, or moisture, these starter motors are built to last. They feature robust components that ensure long-lasting performance, even in the most challenging environments. This makes them an ideal choice for both off-road and industrial applications.

Energy Efficiency and Lower Maintenance Costs

Lucas TVS starter motors are designed to be energy efficient. The gear-reduction models, in particular, draw less current from the battery, which reduces the overall power consumption. This means fewer demands on the battery, leading to improved fuel efficiency and lower operating costs. In addition, these starter motors are known for their low maintenance requirements, further reducing the cost of ownership over time.

Applications of Lucas TVS Starter Motors

Lucas TVS starter motors are versatile and can be used in a wide range of vehicles and machinery. From passenger cars to heavy-duty industrial equipment, they are built to cater to various applications.

Passenger Vehicles

In passenger vehicles, both direct-drive and gear-reduction starter motors from Lucas TVS are widely used. The gear-reduction models, in particular, are favoured in modern cars due to their compact size and energy efficiency. These motors ensure smooth and quick engine starts, even in cold weather conditions.

Commercial Vehicles

For commercial vehicles like trucks, buses, and delivery vans, Lucas TVS direct-drive starter motors are an excellent choice. They offer the high torque necessary to start larger diesel engines, making them suitable for heavy-duty applications where reliability is critical.

Industrial Machinery

Lucas TVS starter motors are not limited to vehicles. They are also used in industrial machinery. From construction equipment to agricultural machinery, these motors provide the power needed to start engines in demanding environments.

Special Applications in Electric Vehicles and Hybrids

With the growing trend towards electric vehicles (EVs) and hybrid technology, Lucas TVS has also adapted its starter motors for use in these vehicles. Special applications of Lucas TVS starter motors in hybrids ensure efficient engine starts and integration with electric propulsion systems. These motors are designed to meet the unique requirements of electric and hybrid vehicle technology, offering the same reliability and performance expected from Lucas TVS.

Frequently Asked Questions

Q1: What should I do if my Lucas TVS starter motor makes a grinding noise during startup?

If your Lucas TVS starter motor produces a grinding noise, it could indicate worn teeth on the pinion gear or flywheel. These are critical Lucas TVS starter motor parts that ensure smooth engagement with the engine. Continuing to operate the motor may worsen the issue. It’s advisable to consult a professional mechanic and refer to the Lucas TVS starter motor catalogue to identify compatible replacement parts.

Q2: How can I prevent my Lucas TVS starter motor from overheating?

To prevent your Lucas TVS starter from overheating, avoid prolonged cranking beyond 10–15 seconds. Allow intervals between attempts and ensure your battery is fully charged. Overheating can lead to damage of internal Lucas TVS starter motor parts, shortening the life of the unit. Routine maintenance and part checks, as recommended in the Lucas TVS starter motor catalogue, can help ensure optimal performance.

Q3: Can I install a Lucas TVS starter motor by myself?

Installation of a Lucas TVS starter motor should ideally be performed by a qualified technician. While technically skilled individuals may attempt it, proper alignment, torque application, and understanding of Lucas TVS starter motor parts are essential to avoid misinstallation. Always refer to the manufacturer’s guidelines or the Lucas TVS starter motor catalogue for correct installation procedures.

Q4: Why does my starter motor click but not start the engine?

If your Lucas TVS starter motor clicks but doesn’t turn the engine over, the problem could be a weak battery, loose wiring, or a faulty solenoid. Since the solenoid is a key component in many Lucas TVS starter motor parts, it may require inspection or replacement. Using the Lucas TVS starter motor catalogue, you can find the exact solenoid type compatible with your motor.

Q5: Where can I find genuine Lucas TVS starter motor parts?

Genuine Lucas TVS starter motor parts are available through authorized dealers, auto electrical shops, and online marketplaces that specialize in OEM spares. Referring to the Lucas TVS starter motor catalogue can help you identify the exact part numbers and specifications for your specific vehicle model, ensuring compatibility and reliability.

Q6: How do I choose the right Lucas TVS starter motor for my vehicle?

To choose the correct Lucas TVS starter motor, check your vehicle’s make, model, and engine specifications. The Lucas TVS starter motor catalogue provides a comprehensive list of starter models and part numbers suited for different vehicles. You can also consult a trusted concrete plant manufacturer or automotive technician to confirm compatibility.

Q7: What are the signs that I need to replace my Lucas TVS starter?

Signs that your Lucas TVS starter may need replacement include slow cranking, grinding noises, clicking sounds, or complete failure to start. If troubleshooting common issues doesn’t resolve the problem, it may be time to consult the Lucas TVS starter motor catalogue for a suitable replacement model or specific Lucas TVS starter motor parts.

Q8: Are Lucas TVS starter motors compatible with commercial and heavy-duty vehicles?

Yes, Lucas TVS starter motors are designed to support a wide range of applications, including commercial vehicles, buses, and heavy-duty equipment. The Lucas TVS starter motor catalogue includes models built for higher torque output and durability, making them ideal for demanding usage conditions.